Industrial Gear Units. Wind Turbine Gear Unit

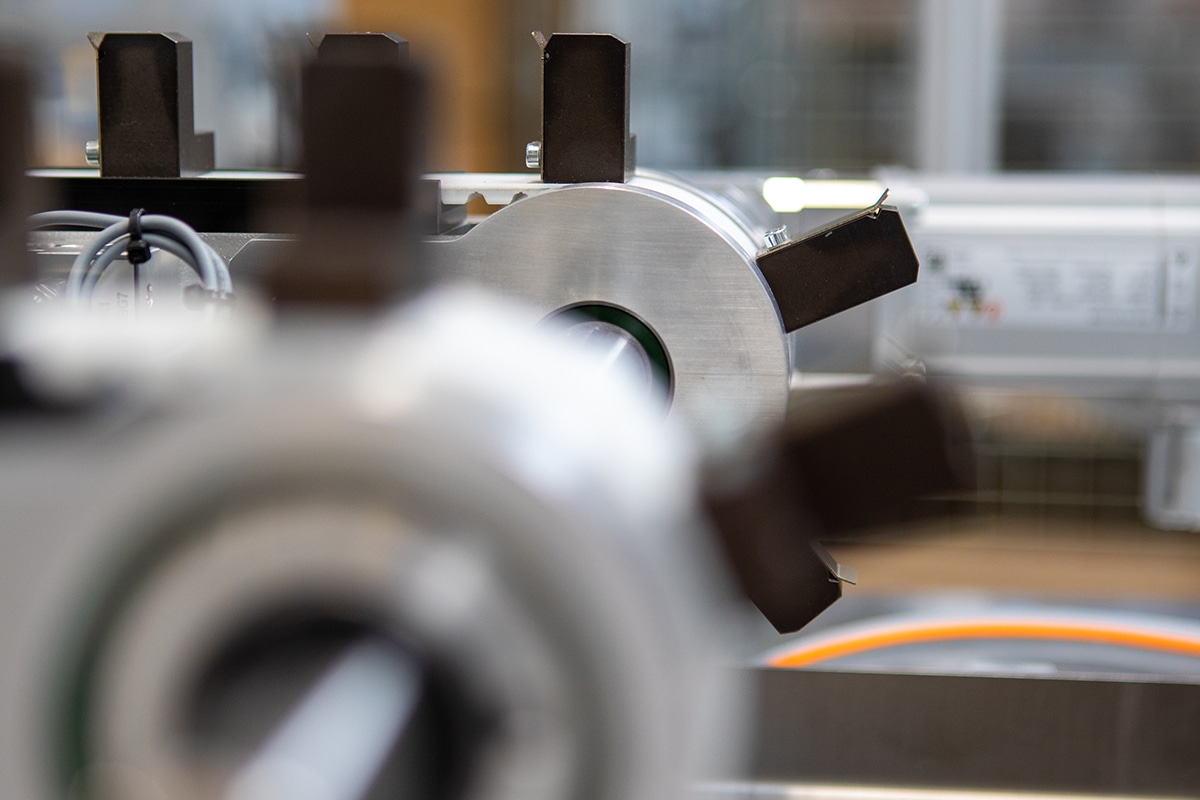

Operating conditions with different combinations of speed and torque place high requirements on gearboxes in wind power. Special materials as well as innovative coating methods ensure an optimal operation – even at extremely high pressures and very low speeds. An intelligent planetary bearing system ensures a uniform load distribution in the respective operating conditions and optimizes the meshing contact of the gears. The intelligent planetary bearing system in connection with the use of five planets maximizes the power density.

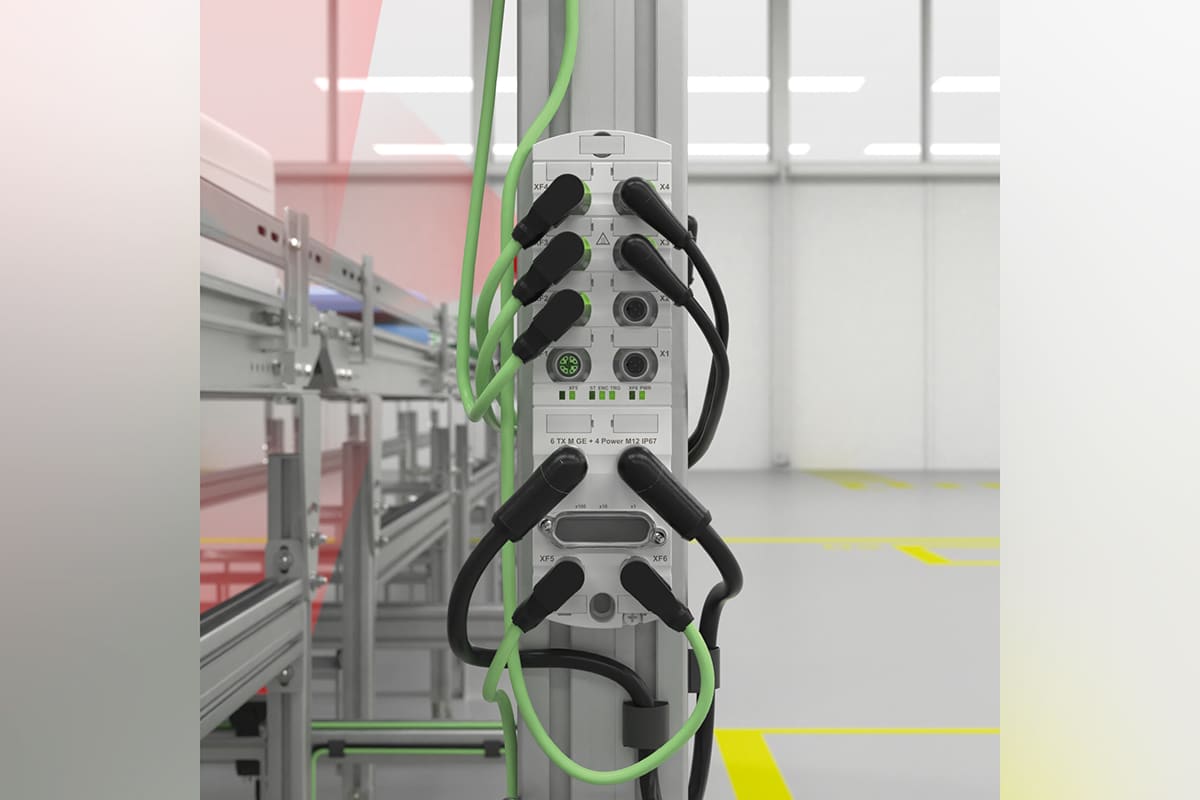

The EQ-Gear® is suitable both for low and medium speed platform configurations in a coaxial design as well as for the highspeed drive train with an axial offset generator connection. With the coaxial platform configuration, the wire required for the pitch control can easily be guided through the gear unit between the input shaft and output shaft. The unique wireless temperature monitoring ensures the remote maintenance of slide bearings as well as the optimized self-adjusting load distribution between the planetary stages. This results in an excellent overall system that is designed specifically for the drive train of the wind turbine: with a RENK coupling and a RENK condition monitoring system. Optionally, the entire system, including the electrical connection, can be simulated and validated.

Features:

- Optimal load distribution

- Certified as per IEC and GL directives

- Reduced weight and parts variety

- Maximum power density

- Intelligent state monitoring

For more information, contact our sales team at info@azhollinkgroup.com